The main factors affecting the price and supply of iPhone X series screens in Q4 2021 are as follows:

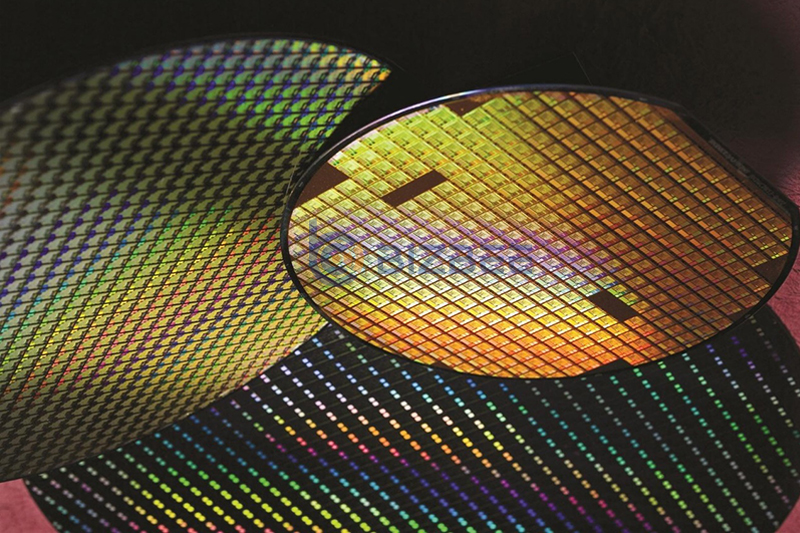

1.The upstream raw materials of the cell phone repair industry chain like LCD panels, wafers, TDDI chips, display driver ICs and touch ICs are in short supply, and the shortages and price increases may continue until 2022.

From the supply side:

Wafers have been in short supply since Q3 of 2020. The incentive is that after Huawei’s ban, the demand for stocking is preempted; by Q4, due to concerns about the intensification of the epidemic, the chip supply will be tight or even out of stock. Terminal manufacturers placed repeated orders and prepared goods in a panic to avoid supply chain risks, resulting in a mismatch between market supply and demand. Taiwanese companies in China, whose production capacity occupies more than 60% of panel driver ICs in Q1-Q2 this year, are facing the "big test" of the epidemic, water shortage, and power outages. The frequent occurrence of "black swan" incidents such as the power outage of the large wafer fab UMC's Hsinchu plant, the Fukushima earthquake in Japan, and the power outages during the Texas blizzard have made wafer shortages worse.

From the demand side:

Affected by the epidemic, the global demand for telecommuting and online classes has increased, driving the rapid growth of server demand. The development of online economy has driven the continuous growth of global server shipments. For example, driven by the growth of online office demand, the global PC shipment in 2020 will be 297 million units, with an annual growth rate of 11%, which is the highest annual growth rate in recent 10 years, which will directly drive the demand for consumer CPU, DRAM chip, storage chip, power management chip and other related chips. The global chip demand is growing steadily due to factors such as the improvement of the penetration rate of automobile electrification / Networking / intelligence, the improvement of the penetration rate of 5g mobile phones and base stations, and the development of the Internet of things such as smart home.

These chip applications with high growth space and high gross margin have a high degree of overlap between the production capacity and the demand for display driver IC, which will inevitably crowd out the supply capacity of wafer foundry and packaging and testing plants for display driver IC.

2. The power cuts policy has caused the production decrease and price increase of the upstream resource and raw materials, and the supply of production capacity continues to be tight. The long-term "dual control of energy consumption" affects the performance growth; The impact of the middle and lower reaches mainly comes from the cost side pressure brought by the rise in the prices of upstream energy and raw materials, and the profits of the manufacturing industry are squeezed.

There are two main reasons for power cuts: First, insufficient coal production and insufficient coal stock in power plants. High coal prices have led to weak thermal power plants’ willingness to generate electricity, leading to an imbalance in power supply and demand. Second, local governments should deal with the "dual control" of energy, actively implement the policy of "Carbon Neutral", and take production restriction measures for enterprises in specific industries by means of power outage and restriction.

3. Many factories are understaffed in the second half of 2021, resulting in low production capacity.

Based on the above reasons, the aftermarket screens for iPhone X series in Q4 2021 are likely to experience price increases and tight supply. Please pay close attention to the market trends and prepare for the goods in advance.